- DL manuals

- Eco Drive

- Inverter

- V5−H

- Manual

Eco Drive V5−H Manual

V&T Technologies Co., Ltd.

http://www.ecodrivecn.com

Foreword

The V5

−H series inverter is a kind of high-performance vector control inverter

provided by V&T Technologies Co., Ltd. The product adopts speed sensorless

vector control technology technology, the internationally leading technology, to

offer excellent control performance and combines the application

characteristics of China to further enhance the product reliability, environment

adaptability and customized and industrialized design. It can better meet the

demands of the various drive applications.

Summary of V5−H

Page 1

V&t technologies co., ltd. Http://www.Ecodrivecn.Com foreword the v5 −h series inverter is a kind of high-performance vector control inverter provided by v&t technologies co., ltd. The product adopts speed sensorless vector control technology technology, the internationally leading technology, to of...

Page 2

V&t technologies co., ltd. Http://www.Ecodrivecn.Com excellent performance control mode vector control 1: offering excellent vector control performance and insensitive to motor parameters. Startup torque: 0.50hz 180% rated torque speed adjustment range: 1:100 speed stabilization precision: ± 0.5...

Page 3

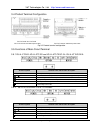

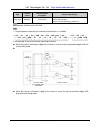

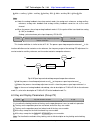

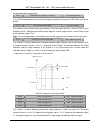

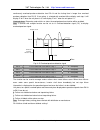

V&t technologies co., ltd. Http://www.Ecodrivecn.Com fig. 1 quick acceleration/deceleration four-quadrant running in the form of 0hz →forward running 50hz→0hz→reverse running 50hz→0hz realizing real tripless operation with excellent current and voltage control technology, 0.1s repetitive and alter...

Page 4

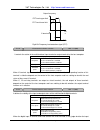

V&t technologies co., ltd. Http://www.Ecodrivecn.Com fig. 2 the inverter realizes stable control of current and voltage and will not trigger under any acceleration/deceleration condition as well as stable operation condition large torque and stable operation at low frequency under vector control w...

Page 5

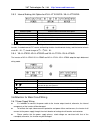

V&t technologies co., ltd. Http://www.Ecodrivecn.Com unique instantaneous mains failure reaction upon the instantaneous mains failure, the energy of the motor feedback bus will keep the inverter running till the mains resumes normal. When shutdown is caused by long-term power-failure during the op...

Page 6

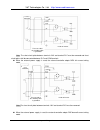

V&t technologies co., ltd. Http://www.Ecodrivecn.Com tracing mode 2: impactlessly pull down the motor from high-speed to low speed and then accelerate to normal speed. Fig. 5 tracing and smooth startup after frequency reduction upon the motor high-speed free rotation unique quick dc braking within...

Page 7

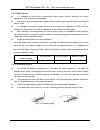

V&t technologies co., ltd. Http://www.Ecodrivecn.Com high reliability design meeting the relevant international product standards iec61800-2 general requirements–rating specifications for low voltage adjustable frequency a.C. Power drive systems iec61800-3 emc product standard including specific t...

Page 8

V&t technologies co., ltd. Http://www.Ecodrivecn.Com improve the protection capability of the system. It is applicable to the applications with dusty and corrosive environment, such as wire-drawing machine, printing and dyeing and ceramics. Wide voltage range design: the dc operating voltage range i...

Page 9

V&t technologies co., ltd. Http://www.Ecodrivecn.Com rich and flexible functions multiple frequency reference modes, flexible and convenient for operation operation panel reference (digital reference). The operation panel can be used to conduct ∨/∧ adjustm ent on the frequency reference. Terminal ...

Page 10

V&t technologies co., ltd. Http://www.Ecodrivecn.Com with unique multifunctional button m, the following functions can be defined: 1) jog 2) emergency shutdown 1 (fastest shutdown) 3) emergency shutdown 2 (free shutdown) 4) reference mode switch through operating command (operation panel reference →...

Page 11

V&t technologies co., ltd. Http://www.Ecodrivecn.Com customized functions multiple function code display modes base: basic menu mode (refer to 5.1 basic menu function code parameter table), displays all the function codes. Fast: fast menu mode, is especially suitable for the naive users. Ndft: non-l...

Page 12

V&t technologies co., ltd. Http://www.Ecodrivecn.Com vacuum pump, grinding machine, female thread extrusion machine. With the acceleration/deceleration time up to 10 hours, it is applicable to the bobbiner and other equipment of the textile industry. It supports the overload protection with motor te...

Page 13

V&t technologies co., ltd. Http://www.Ecodrivecn.Com typical industry applications digital control machine tool compact structure: the size is equal to 70% of the inverter of the same power. Low speed precise processing: the excellent low-frequency torque performance can meet the processing demand o...

Page 14

V&t technologies co., ltd. Http://www.Ecodrivecn.Com equipment when receiving the positioning signal. extrusion machine energy saving extrusion machine interface board: it can realize best flow and pressure distribution relation in different processes by receiving the extrusion machine feedback si...

Page 15

V&t technologies co., ltd. Http://www.Ecodrivecn.Com safety precautions description of safety marks: danger: the misuse may cause fire, severe injury, even death. Note: the misuse may cause medium or minor injury and equipment damage. use danger danger this series of inverter is used to control th...

Page 16

V&t technologies co., ltd. Http://www.Ecodrivecn.Com wiring danger danger the wiring must be conducted by qualified electricians. Otherwise, there exists the risk of electric shock or inverter damage. Before wiring, confirm that the power supply is disconnected. Otherwise, there exists the risk of...

Page 17

V&t technologies co., ltd. Http://www.Ecodrivecn.Com operation danger danger power supply can only be connected after the wiring is completed and the cover is installed. It is forbidden to remove the cover in live condition; otherwise, there exists the risk of electric shock. When auto failure res...

Page 18

V&t technologies co., ltd. Http://www.Ecodrivecn.Com note note the circuit boards have large scale cmos ic. Please do not touch the board to avoid the circuit board damage caused by electro static. others danger danger it is forbidden to modify the inverter unauthorizedly; otherwise, personal inju...

Page 19: Contents

V&t technologies co., ltd. Http://www.Ecodrivecn.Com contents chapter 1 introduction to v5-h series inverter ..................................................................................1 1.1 product model description ................................................................................

Page 20

V&t technologies co., ltd. Http://www.Ecodrivecn.Com 5.2 user’s parameter record ................................................................................................................. 60 5.3 user’s connection diagram ...........................................................................

Page 21

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 1 introduction to v5 −h series inverter 1 chapter 1 introduction to v5 −h series inverter 1.1 product model description the digits and letters in the inverter model field on the nameplate indicate such information as the product series, po...

Page 22

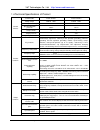

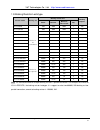

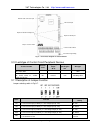

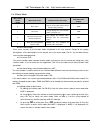

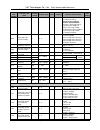

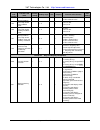

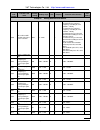

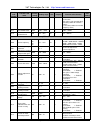

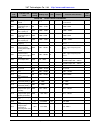

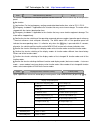

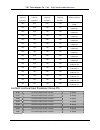

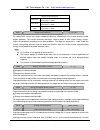

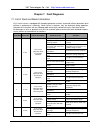

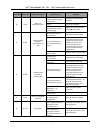

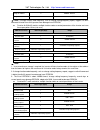

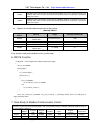

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 1 introduction to v5 −h series inverter 2 1.3 product series v5 −h−4t □□□ g three-phase 400v constant torque/heavy-duty application power (kw) 0.75 1.5 2.2 3.7 5.5 7.5 11 15 18.5 22 30 37 45 55 75 motor power (kw) 0.75 1.5 2.2 3.7 5.5 7....

Page 23

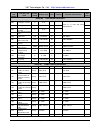

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 1 introduction to v5 −h series inverter 3 v5 −h−4t □□□ l three-phase 400v variable torque/light-duty application power (kw) 1.5 2.2 3.7 5.5 7.5 11 15 18.5 22 30 37 45 55 75 90 motor power (kw) 1.5 2.2 3.7 5.5 7.5 11 15 18.5 22 30 37 45 5...

Page 24

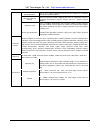

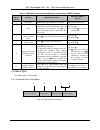

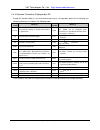

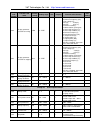

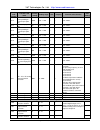

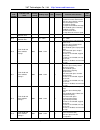

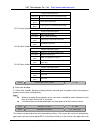

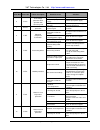

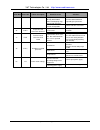

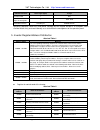

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 1 introduction to v5 −h series inverter 4 1.4 technical specifications of product control features control mode vector control 1 vector control 2 startup torque 0.50hz 180% 0.25hz 180% speed adjustment range 1:100 1:200 speed stabilization...

Page 25

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 1 introduction to v5 −h series inverter 5 independent duct the full series adopts independent duct design and supports the installation of heatsink outside the cabinet universal expansion interface universal expansion board equipped with c...

Page 26

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 1 introduction to v5 −h series inverter 6 1.5 product component name v5 −h−2t0.4g~v5−h−2t2.2g v5 −h−4t7.5g/11l and below power class v5−h−4t11g/15l and above power class fig. 1 −1 product component name 1.6 product outline, mounting dimens...

Page 27

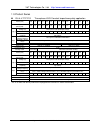

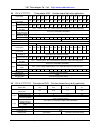

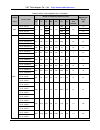

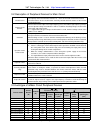

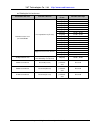

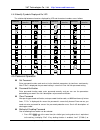

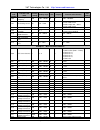

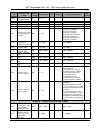

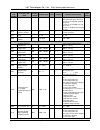

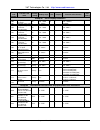

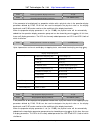

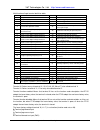

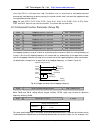

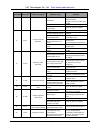

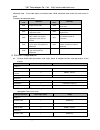

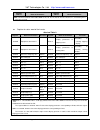

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 1 introduction to v5 −h series inverter 7 product outline, mounting dimension, and weight voltage class inverter model outline and mounting dimension (mm) approximate weight (kg) w h d w1 h1 d1 t1 mounting hole diameter 200v v5 −h−2t0.4g 1...

Page 28

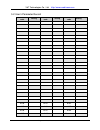

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 1 introduction to v5 −h series inverter 8 voltage class inverter model outline and mounting dimension (mm) approximate weight (kg) w h d w1 h1 d1 t1 mounting hole diameter 400v v5 −h−4t400g v5 −h−4t450l 810 1358 425 520 1300 210 4.0 14 215...

Page 29

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 1 introduction to v5 −h series inverter 9 1.7 operation panel outline and mounting dimension shuttle type operation panel (v6 −dp01) button type operation panel (v6 −dp02) rear view of operation panel fig.1-3 operation panel outline and mo...

Page 30

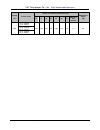

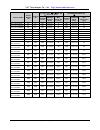

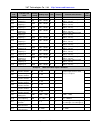

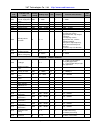

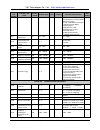

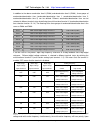

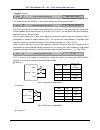

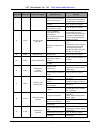

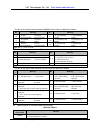

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 1 introduction to v5 −h series inverter 1 0 1.9 braking resistor lectotype inverter model braking unit braking resistor unit braking torque% power resistor minimum limit resistor qty. V5 −h−2t0.4g b u i l t - i n a s s t a n d a r d 70w 20...

Page 31

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 2 inverter installation 11 chapter 2 inverter installation 2.1 environment for product installation avoid installing the product in the sites with oil mist, metal powder and dust. avoid installing the product in the sites with hazardou...

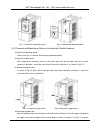

Page 32

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 2 inverter installation 12 note: when the v5 −h−2t0.4g~v5−h−2t2.2g and v5−h−4t7.5g/11l and below power class inverters are mounted side by side in the cabinet, please remove the upper dust guard and the lower leading board. Fig. 2 −2 mount...

Page 33

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 2 inverter installation 13 fig. 2 −3 removal of operation panel fig.2−4 mounting of operation panel 2.3.2 removal and mounting of covers of inverter with plastic enclosure removal of operation panel please refer to 2.3.1 removal and mounti...

Page 34

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 2 inverter installation 14 press the lower part of the upper cover in direction 2 as shown in fig.2 −7, until the “crack” sound is heard. Mounting of lower cover insert the upper claw grab on the lower cover into the groove of the upper co...

Page 35

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 2 inverter installation 15 fig.2 −9 removal of cover fig.2−10 mounting of cover mounting of operation panel please refer to 2.3.1 removal and mounting of operation panel. Note: do not directly mount the cover with operation panel on the in...

Page 36

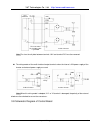

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 3 wiring of inverter 16 chapter 3 wiring of inverter 3.1 connection of the product and peripheral devices fig.3 −1 connection diagram of the product and peripheral devices power supply contactor input ac reactor dc reactor inverter groundi...

Page 37

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 3 wiring of inverter 17 3.2 description of peripheral devices for main circuit circuit breaker the capacity of the circuit breaker shall be 1.5 ~ 2 time of the rated current of the inverter. The time features of the circuit breaker shall f...

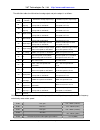

Page 38

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 3 wiring of inverter 18 inverter model circuit breaker (a) contactor (a) r/l1, s/l2, t/l3, ⊕ 1, ⊕ 2/b1, b2, Ө , u/t1, v/t2, w/t3 grounding terminal pe terminal screw tightenin g torque (n·m) wire specificatio n (mm 2 ) terminal screw tight...

Page 39

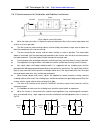

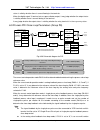

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 3 wiring of inverter 19 3.4 product terminal configuration v5 −h−2t0.4g~v5−h−2t2.2g v5 −h−4t7.5g/11l and below power class v5−h−4t11g/15l and above power class fig.3 −2 product terminal configuration 3.5 functions of main circuit terminal ...

Page 40

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 3 wiring of inverter 20 3.5.3 internal braking unit option for v5 −h−4t18.5g/22l~v5−h−4t75g/90l terminal symbol terminal name and function description r/l1, s/l2, t/l3 three-phase ac input terminal b1, Ө ﹡ dc reactor connecting termina﹡ b1...

Page 41

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 3 wiring of inverter 21 3.6.2 motor wiring it is forbidden to short circuit or ground the inverter output terminal, otherwise the internal components of the inverter will be damaged. Avoid short circuit the output cable and the inverter en...

Page 42

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 3 wiring of inverter 22 3.6.4 countermeasures for conduction and radiation interference fig.3 −4 noise current illustration when the input noise filter is installed, the wire connecting the filter to the inverter input power end shall be a...

Page 43

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 3 wiring of inverter 23 fig.3 −5 application of inductive load surge suppressor.

Page 44

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 3 wiring of inverter 24 3.7 terminal wiring fig.3 −6 terminal wiring diagram (take v5−h−4t5.5g/7.5l as an example).

Page 45

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 3 wiring of inverter 25 3.8 functions of control circuit terminals type terminal symbol terminal function description technical specification terminal 485 485+ positive end of 485 differential signal rate: 4800/9600/19200/38400/57600bps up...

Page 46

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 3 wiring of inverter 26 type terminal symbol terminal function description technical specification relay output ra/rb/rc relay output ra-rb: normally closed ra-rc: normally open contact capacity: 250vac/1a, 30vdc/1a note: ﹡ if the user con...

Page 47

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 3 wiring of inverter 27 note: the short circuit plate between terminal +24v and terminal plc must be removed and short circuit plate shall be connected between plc and com terminals. when the external power supply is used, the external c...

Page 48

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 3 wiring of inverter 28 note: the short circuit plate between terminal +24v and terminal plc must be removed. the wiring modes of the multi-functional output terminals when the internal +24v power supply of the inverter and external powe...

Page 49

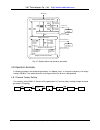

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 3 wiring of inverter 29 fig.3-7 schematic diagram of control board 3.10 lectotype of control circuit peripheral devices terminal number terminal screw tightening torque (n·m) wire specification mm 2 wire type +10v, ai1, ai2, ai3, 485+, 485...

Page 50

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 4 using instructions of operation panel 30 chapter 4 using instructions of operation panel 4.1 introduction to operation panel shuttle type operation panel (v6-dp01) key-type operation panel (v6-dp02) fig. 4 −1 display unit of operation pa...

Page 51

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 4 using instructions of operation panel 31 4.3 description of keys on operation panel note: the enter key of shuttle type operation panel is equivalent to prg key. Using prg key continuously can realize fast browse of all function codes. S...

Page 52

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 4 using instructions of operation panel 32 table 4-1 method of using multi-function key and meanings of multi indicator definition of m key (p2.01) function meanings of function meanings of multi indicator 0 no function multi-function key ...

Page 53

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 4 using instructions of operation panel 33 dividing the first level menu password action area function code area group number in area function code range protection area of user password p0.00 user operation area (p area) p0 group p0.00 ~ ...

Page 54

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 4 using instructions of operation panel 34 structure of first level menu ... U0. 00 u1. 00 p0. 00 p0. 01 ... P0. 16 ... ... Pe. 00 pe. 01 c0. 00 fy c0 p0 pe d1 ... ... D2 u1 ... A0 菜单结构 u0 fig. 4 −3 structure of first level menu 4.4.2 form...

Page 55

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 4 using instructions of operation panel 35 4.4.3 menu mode menu mode setting (p0.02) menu mode name visible function code range operation panel display 0 basic menu see 5.1 for the table of basic menu function code parameter base 1 fast me...

Page 56

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 4 using instructions of operation panel 36 4.4.4 common characters displayed by led except the function codes in first and second level menus, the operation panel will also display the following characters as shown in the following table: ...

Page 57

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 4 using instructions of operation panel 37 4.4.5 identify symbols displayed via led the relationship between characters displayed by led and characters/numbers are as follows: led display meanings of characters led display meanings of char...

Page 58

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 4 using instructions of operation panel 38 “loc2”(p2.00=2) or “loc3”(p2.00=3) is displayed. 2. No key operation for continuous 5 minutes. 3. Power on again 4.6 lock/unlock keys lock keys set the function of locking keys select the p2.00 ...

Page 59

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 4 using instructions of operation panel 39 4.7 operation panel display and key operation 4.7.1 classification of display status there are 8 types of display status of operation panel: sn status meaning 1 display status of stopping paramete...

Page 60

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 4 using instructions of operation panel 40 display parameters at stopping status modify frequency directly time out and stop modifying fault occurs fault reset time out and stop modifying display parameters at running status stop rst run p...

Page 61

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 4 using instructions of operation panel 41 4.8.2 setting frequency for example, setting p0.05=25.00hz. 4.8.3 setting password for example, setting user password p0.00 to 0003. 4.8.4 password verification assume that the function codes afte...

Page 62

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 4 using instructions of operation panel 42 before power up, confirm the wiring is correct setting p0.01=5 restore the factory setting setting max output voltage p0.12 and motor basic frequency p0.15 according to motor nameplate press m key...

Page 63

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 5 list of parameters 43 chapter 5 list of parameters meanings of each item in function code parameter table item m e a n i n g s function code number the number of function code, such as p0.00 function code name the name of function code, ...

Page 64

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 5 list of parameters 44 function code number function code name factory setting setting range unit property function code selection user setting process close loop control; 3: composite control; vector control 2 without encoder speed feedb...

Page 65

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 5 list of parameters 45 function code number function code name factory setting setting range unit property function code selection user setting auxiliary calculation 4: take maximum value; 5: take minimum value p1.05 analog feedback close...

Page 66

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 5 list of parameters 46 function code number function code name factory setting setting range unit property function code selection user setting p2.02 display parameter selection at running 1cb0 0 ~ ffff / ○ led ones place: 0: reference fr...

Page 67

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 5 list of parameters 47 function code number function code name factory setting setting range unit property function code selection user setting p3.06 dc braking initial frequency 0.00 0.00 ~ 300.00 hz × 0.00 ~ 300.00hz p3.07 dc braking cu...

Page 68

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 5 list of parameters 48 function code number function code name factory setting setting range unit property function code selection user setting frequency 1 (p0.13 ~ p0.14) p4.23 multi-section frequency 2 8.00 0.00 ~ 300.00 hz ○ upper / lo...

Page 69

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 5 list of parameters 49 function code number function code name factory setting setting range unit property function code selection user setting group p6 analog reference parameter p6.00 ai1 to ai3 and di analog value input curve selection...

Page 70

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 5 list of parameters 50 function code number function code name factory setting setting range unit property function code selection user setting p6.12 per-unit value b1 corresponding to curve3 input point a1 100.0 0.0 ~ 110.0 % ○ 0.0~110.0...

Page 71

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 5 list of parameters 51 function code number function code name factory setting setting range unit property function code selection user setting p7.04 ao2 terminal output function selection 49 48 ~ 71 / ○ p7.05 ao1 gain 100.0 0.0 ~ 200.0 %...

Page 72

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 5 list of parameters 52 function code number function code name factory setting setting range unit property function code selection user setting p8.02 number of pulse per turn for single phase pulse 1000 1 ~ 9999 / × 1 ~ 9999 p8.03 proport...

Page 73

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 5 list of parameters 53 function code number function code name factory setting setting range unit property function code selection user setting 1: sensor mode; 2: no action tens place: low speed derating 0: action(suitable for common moto...

Page 74

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 5 list of parameters 54 function code number function code name factory setting setting range unit property function code selection user setting 1: inverter overload pre-alarm, relative to inverter rated current; led tens place: action sel...

Page 75

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 5 list of parameters 55 function code number function code name factory setting setting range unit property function code selection user setting led hundreds place: reserve; led thousands place: reserve; 0: fault is not shileded, stopped u...

Page 76

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 5 list of parameters 56 function code number function code name factory setting setting range unit property function code selection user setting 2: clear upon standby hundreds place: terminal up/dn adjustment setting 0: only enabled when m...

Page 77

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 5 list of parameters 57 function code number function code name factory setting setting range unit property function code selection user setting group pd vector control 2 parameters pd.00 speed/torque control 0 0 ~ 1 / ○ 0: reserved; 1: re...

Page 78

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 5 list of parameters 58 function code number function code name factory setting setting range unit property function code selection user setting group d0 fault record parameters d0.00 fault type record 2 0 0~62 / * refer to 7.1 fault and a...

Page 79

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 5 list of parameters 59 function code number function code name factory setting setting range unit property function code selection user setting group d2 use of display parameters d2.00 temperature of heatsink 1 0.0 0.0 ~ 100.0 ºc * 0.0 ~ ...

Page 80

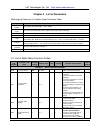

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 5 list of parameters 60 5.2 user’s parameter record function code setting function code setting function code setting d1.00 d1.01 d1.02 d1.03 d1.04 d1.05 d1.06 d1.07 d1.08 d1.09 d1.10 recorder:.

Page 81

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 5 list of parameters 61 5.3 user’s connection diagram control circuit powe motor main circuit control circuit.

Page 82

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 62 chapter 6 parameter description 6.1 basic function parameter (group p0) this function is used to prevent the irrelevant personnel from inquiring and changing the parameters, so as to protect the safety of the inv...

Page 83

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 63 2: menu mode of non-leave-factory value function code: the operation panel only displays the parameters different from the leave-factory values. When the technical personnel perform onsite maintenance, to quickly...

Page 84

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 64 physical parameter. The adjustment result will be added to the open loop frequency reference of the inverter, so as to ensure the constancy of the physical parameter through speed control. Refer to the descriptio...

Page 85

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 65 multi-functional terminals x1~x7. Refer to the description of p5.00~p5.06 and p5.11. 2: host computer mode: perform the run, stop, forward/reverse operation of the inverter through communication. Refer to the app...

Page 86

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 66 in linear mode. Acceleration time =p0.08×set frequency/p0.11; deceleration time =p0.09×set frequency/ p0.11. When p0.10 is set as a non-zero value, it indicates that there is s curve time, and the acceleration an...

Page 87

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 67 effect of the torque boost function: upon the vector control 1, when the inverter operation at low-frequency, increase the output voltage, and offset the stator voltage drop to product enough torque, so as to ens...

Page 88

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 68 fig.6-4 process open loop main and auxiliary reference calculation 0 open loop combination reference f com =main reference f m +auxiliary reference f a 1: main reference - auxiliary reference: the auxiliary frequ...

Page 89

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 69 3: main reference + auxiliary reference-50%: the auxiliary reference value subtracts the bias equal to 50% of the auxiliary reference full range value and then superimposes on the main reference. Fig.6-7 process ...

Page 90

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 70 open loop combination reference f com =min {main reference f m , auxiliary reference f a } note: when the corresponding frequency of the combination value f com exceeds the upper or lower limit of the frequency, ...

Page 91

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 71 0: main + auxiliary; 1: main - auxiliary; 2: auxiliary -50%; 3: main+ auxiliary-50%; 4: max; 5: min. Note: under the analog feedback close loop control mode, the analog main reference, analog auxiliary reference,...

Page 92

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 72 to facilitate the operation, the frequent operation can be set on the multi-functional key of the operation panel. 0: no function. 1: jog function: for the jog frequency and jog acceleration/deceleration time, re...

Page 93

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 73 if the parameter to be displayed has proportion relation with a physical value in the operation display parameter defined by p2.02, p2.04 can be used to designate the physical value as the display benchmark, and ...

Page 94

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 74 6.4 startup/stop parameter (group p3) different startup modes can be adopted for different applications. 0: the inverter begins to run from the startup frequency p3.03 and accelerates to the setting frequency aft...

Page 95

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 75 p3.06 sets the initial frequency at the beginning of dc braking current injection during the shutdown p3.07 sets the dc braking current value. This value is presented as the percentage of the rated current of the...

Page 96

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 76 6.5 multi-section parameter (group p4) it is to determine the different v/f curves under vector control 1 mode. Fig. 6 −12 v/f curve fig.6-13 multi-section v/f curve p4.00=0: applicable to the constant torque loa...

Page 97

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 77 in addition to the above acceleration time 0 (p0.08) and deceleration time 0 (p0.09) , three groups of acceleration/deceleration time (acceleration/deceleration time 1, acceleration/deceleration time 2, accelerat...

Page 98

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 78 analog feedback operation, the multi-section digital voltage reference is in priority to other reference modes. It can be used as process open loop frequency reference. Different multi-section frequency reference...

Page 99

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 79 multi-section frequency terminal 1 multi-section frequency terminal 3 multi-section frequency terminal 2 multi-section frequency terminal 1 setting frequency off off off off open loop frequency p0.05 off off off ...

Page 100

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 80 multi-functional input terminal definition table: sn function definition sn function definition 0 jog forward 27 shutdown via terminal with dc braking 2 1 jog reverse 28 counter trigger input 2 forward (fwd) 29 c...

Page 101

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 81 3: terminal reverse run input (rev) the functions of above items 0 to 3 are only enabled in the terminal running command reference mode (p0.06=1). Interlocking of running command and jog command means that the jo...

Page 102

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 82 19: external failure input when this terminal is enabled, inverter will stop running and display “e.Out” failure. 20: terminal failure reset input this terminal is used to implement failure reset, which can also ...

Page 103

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 83 48: command switching to operation panel 49: command switching to terminal 50: command switching to host computer the above three functions are set to facilitate the switching of running command reference mode. W...

Page 104

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 84 69~98: reserved. It can properly enlarge the setup value of p5.07 to improve the anti-interference capability of the terminal. The longer the terminal filter time is, the longer the delay time of the terminal act...

Page 105

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 85 fig.6-16 three-line running mode 1 the terminal xi(i=1~7) has set “4: three-line mode rotation control” function. Fig 6-16, when k3 is closed, fwd and rev controls are enabled; when k3 is disconnected, fwd and re...

Page 106

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 86 reaches the value of p5.13. Note: p5.12 cannot be set to a value of higher than p5.13, and the counter pulse signal frequency range is 0hz to 200hz. The voltage range is 24v±20%. Set xi (ii=1 to 7) terminal to “2...

Page 107

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 87 10v corresponding to the maximum input pulse frequency p5.10. When current analog value input is selected, please refer to fig.6-20. When “calibration by curve is not necessary” is selected, the maximum analog in...

Page 108

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 88 fig.6 −21 setup frequency characteristics curve (positive effect) fig.6 −22 setup frequency characteristics curve (negative effect) curve 3 and curve 4 are basically the same, but that curve 4 has two more settin...

Page 109

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 89 2: reserved; 3: reserved; 4: reserved; 5: motor temperature feedback (overload protection sensor mode); 6: reserved tens place ai1 function selection, the same as above; hundreds place ai3 function selection, the...

Page 110

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 90 6.8 multi-function output parameter (group p7) y1 and relay terminals can be defined as multifunctional digital signal output. Ao1 and ao2 terminals can be defined as multifunctional analog value output, and the ...

Page 111

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 91 when the output frequency less than fdt2 level lower limit, the signal is disabled. Refer to p7.22 ~ p7.23 for details. 4: pre-warning signal indicating inverter overload or motor overload (ol) when the output cu...

Page 112

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 92 the definition table of multifunctional analog output and pulse output is as follows: function setup output signal selection definition of analog output range definition of pulse output range 48 output frequency ...

Page 113

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 93 to adjust the analog outputs as defined in the above table, it can use this function. The adjusted analog value is the actual output of ao terminal. P7.09 is used to determine the positive and negative polarity o...

Page 114

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 94 will be limited to 0v automatically. This function code determines the maximum frequency output by the terminal y2/do. Refer to p7.01 for details. This function can be used for load change detection. Once the out...

Page 115

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 95 fdt level lower limit output frequency tim e yi terminal time fdt level upper limit fig.6-29: frequency level detection signal (fdt) it controls the action of the multifunctional input terminal or output terminal...

Page 116

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 96 status is valid by whether there is current flowing in the terminals. When the digital output yi terminal acts as open collector output, it may judge whether the output status is valid by whether there is current...

Page 117

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 97 digital voltage reference to implement the multi-section reference function of the close loop. Refer to p4.15 ~ p4.21 for details. As shown in fig.6-30 pid schematic diagram, the higher the kp value is, the faste...

Page 118

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 98 1: continue integration adjustment: the integration value will give immediate response to the change between the reference value and the feedback value unless this value reaches the internal integration limit. Wh...

Page 119

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 99 p9.01 ~ p9.04 are used to set the motor parameters driven by the setup inverter and shall be set properly in accordance with the motor nameplate prior to the use. Note: the power level of the inverter shall match...

Page 120

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 100 the parameter auto-tuning. If there is over current or over voltage failure during the auto-tuning process, it can prolong the acceleration/deceleration time p0.08 and p0.09 properly. If the inverter power does ...

Page 121

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 101 0.35 1 1.75 3.5 5 10 100% 150% 200% motor current(%) action time p9.18=10.0 minutes p9.18=5.0 minutes p9.18=1.0 minutes 0 fig.6-31 motor overload protection characteristics curve (constant torque) 1: sensor mode...

Page 122

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 102 6.11 control parameter (group pa) carrier frequency has an important impact on operations of inverter and motor. When carrier frequency increases, the loss, temperature rise and noise of motor will decrease. If ...

Page 123

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 103 note: this function is only applied to vector control 1. Pa.04 current limit motion selection: 0: invalid. Invalid for both processes of constant speed and acceleration/deceleration. 1: valid. Valid for both pro...

Page 124

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 104 display of operation panel unit place: over-voltage adjustment: 0: no action; 1: action tens place under-voltage adjustment: 0: no action; 1: action hundreds place overmodulation: 0: no action; 1: action by sett...

Page 125

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 105 100%. That is, the use time of the braking unit is fixed to 100.0s action voltage of braking unit can be selected by adjusting pa.11. The motor can be stopped rapidly by energy braking with the appropriate actio...

Page 126

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 106 continuously overload prealarm detection level pa.14 and the lasting time is longer than overload prealarm detection time pa.15. If tens place is selected with overload failure display and stop, it will display ...

Page 127

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 107 display of operation panel unit place: output short circuit to ground abnormality tens place power failure abnormality during running hundreds place input power abnormality thousands place output phase loss eepr...

Page 128

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 108 reset times pa.21, it will alarm then stop. For defaults such as overcurrent or overvoltage occurred occasionally from beginning or during running, the function can be used if you want the equipment keep running...

Page 129

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 109 current acceleration/deceleration time 0(p0.08, p0.09) is valid, the real applied acceleration/deceleration time is 10 times as long as acceleration/deceleration time 0 when ×10 is selected. Setting with operati...

Page 130

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 110 2: operational panel adjustment ∧/∨ disabled. Thousands place: setting of ∧/∨ on operational panel 0: with integral function. When the operation panel ∧/∨ adjustm ent is used to set the frequency, the consistent...

Page 131

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 111 the inverter will be run after power resumes normal. Note: to ensure this function is valid under terminal operating command reference mode, please do not change the status of operating command terminal during s...

Page 132

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 112 2: download parameters (without motor’s parameters). Press prg button to download parameters to the inverter after setting, and will display percentage of copy process when indicating “load”. Parameters of motor...

Page 133

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 113 pc.04 master-slave mode: 0: scia is slave mode and scib is slave mode; 1: scia is master mode and scib is slave mode; 2: scia is slave mode and scib is master mode. Pc.05 master to slave operation address (set b...

Page 134

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 114 adjust proportional gain and integral time for the speed regulator. Proportional gain p: adjust according to rotating inertia of machines connecting with motor. For machines with large rotating inertias, please ...

Page 135

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 115 quadrant i: f orward running driving quadrant ii: reverse running braking quadrant iii: r everse running driving quadrant iv: forward running braking pd.09 pd.08 pd.08 pd.09 output torque motor speed fig. 6-36 t...

Page 136

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 116 time on pd.14 time time operation command flux speed fig. 6-37 pre-magnetizing vector control will control the output current of motor and keep track of current instruction value. Scale and integral gain of curr...

Page 137

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 117 this function defines the input filtering time of speed adjuster (asr). In general, it needs no modification. This function defines the input filtering time of speed adjuster (asr). In general, it needs no modif...

Page 138

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 118 software version number and non-standard version number of product represent the software type. Each inverter has a unique bar code for identification of product and determining product information. D1.01 softwa...

Page 139

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 119 6.17 use of display parameters (group d2) parameters in d2 group are read only parameters. D2.09 indicates the input status of x terminal. 0 indicates open, while 1 indicates close. Hexadecimal combination is ad...

Page 140

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 6 parameter description 120 6.18 user-defined function code displayed/hidden zone parameters (group a0) customize function code menu by function code of group a0. Protect the customized menu with password a0.00.Only function code groups wi...

Page 141

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 7 fault diagnosis 121 chapter 7 fault diagnosis 7.1 list of fault and alarm information v5 −h serial inverter is equipped with complete protection functions to provide efficient protection while utilizing its performance sufficiently. Some...

Page 142

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 7 fault diagnosis 122 failure no. Failure code failure description potential causes solutions 6 e.Ov3 over voltage protection when operation with constant speed motor short to ground check motor wiring abnormal input power supply check inp...

Page 143

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 7 fault diagnosis 123 failure no. Failure code failure description potential causes solutions fan failure check whether fan wirings are well connected. Replace a new fan of the same model rectifier module failure seek for technical support...

Page 144

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 7 fault diagnosis 124 failure no. Failure code failure description potential causes solutions serious unbalance of input power at three phases check whether the unbalance of input power at three phases comply with the requirements burning ...

Page 145

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 7 fault diagnosis 125 failure no. Failure code failure description potential causes solutions 30 e.Ptc motor over temperature(ptc) the motor temperature signal reaches the alarm setting value strengthen ventilation and radiation thermistor...

Page 146

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 7 fault diagnosis 126 failure no. Failure code failure description potential causes solutions the parameters are directly downloaded without undergoing copy and upload operations. Perform download before uploading the parameters control bo...

Page 147

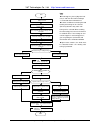

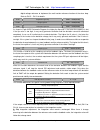

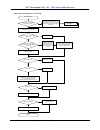

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 7 fault diagnosis 127 7.2 troubleshooting procedures start seek for technical help fault reset no yes no please shut down the power supply immediately to avoid further expansion of the fault no yes seek for technical help seek for technica...

Page 148

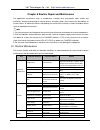

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 8 routine repair and maintenance 128 chapter 8 routine repair and maintenance the application environment (such as temperature, humidity, dust and powder, wool, smoke and oscillation), burning and wearing of internal devices and other fact...

Page 149

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 8 routine repair and maintenance 129 8.2 periodic maintenance it needs to perform periodic inspection on the inverter once every three to six months according to the application environment and work conditions. Item inspection contents ins...

Page 150

V&t technologies co., ltd. Http://www.Ecodrivecn.Com chapter 8 routine repair and maintenance 130 as much as possible under general condition. If the test is unavoidable, please perform the test strictly according to the following procedures, or it may damage the inverter. It shall perform dielectri...

Page 151

V&t technologies co., ltd. Http://www.Ecodrivecn.Com appendix a modbus communication protocol 131 appendix a modbus communication protocol 1. Support protocol support modbus protocol, rtu format, broadcast address 0, slave address “1-247”, “248-255” for reservation. 2. Interface mode rs485: asynchro...

Page 152

V&t technologies co., ltd. Http://www.Ecodrivecn.Com appendix a modbus communication protocol 132 abnormal code. Error code equals to function code +0x80, abnormal code shows the error cause in detail. Examples for abnormal codes: abnormal code definition abnormal code definition 0x01 illegal functi...

Page 153

V&t technologies co., ltd. Http://www.Ecodrivecn.Com appendix a modbus communication protocol 133 register address 2 0x0000~ 0xffff register data 2 0x0000 ~ 0xffff note: if change function code frequently, such as change setting frequency repeat, suggest use 0x41 command is better than 0x16, prevent...

Page 154

V&t technologies co., ltd. Http://www.Ecodrivecn.Com appendix a modbus communication protocol 134 pdu part contents data length (byte) range function code 1 0x17 read the number of bytes in the register 1 0x02~0x20 read data contents 2*read bytes 0x0000~0xffff operating sequence: read firstly and re...

Page 155

V&t technologies co., ltd. Http://www.Ecodrivecn.Com appendix a modbus communication protocol 135 register address name of parameters register address name of parameters note: the virtual terminals from lsb to msb are x1, x2, x3, x4, x5, x6, x7, ai1, ai2, ai3, y1, y2 and relay, bit13 ~ bit15 are res...

Page 156

V&t technologies co., ltd. Http://www.Ecodrivecn.Com appendix a modbus communication protocol 136 the bits for the control command word (0x8000) of the inverter are defined as follows: bit meaning bit meaning 0 0: stop command enable 1: running command enable 3 0: jog command disable 1: jog command ...

Page 157

V&t technologies co., ltd. Http://www.Ecodrivecn.Com appendix a modbus communication protocol 137 0xf001 pe.00 password authentication for the display and hidden areas of the specially authenticated function codes of the inverter, and it will be closed automatically if no operation is performed with...

Page 158

V&t technologies co., ltd. Http://www.Ecodrivecn.Com appendix a modbus communication protocol 138 read the operating frequency of no.1 inverter and the response operating frequency of the inverter is 50.00hz: address function code register address number bytes register contents request 0x01 0x03 0x8...

Page 159

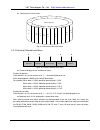

V&t technologies co., ltd. Http://www.Ecodrivecn.Com appendix a modbus communication protocol 139 attached fig.4 connecting multiple inverters to the computer.

Page 160

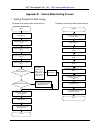

V&t technologies co., ltd. Http://www.Ecodrivecn.Com appendix b control mode setting process 140 appendix b control mode setting process 1. Setting process for auto-tuning parameter auto-tuning under vector control 1 parameter auto-tuning under vector control 2 start setting p0.01=5 setting rated vo...

Page 161

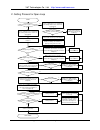

V&t technologies co., ltd. Http://www.Ecodrivecn.Com appendix b control mode setting process 141 2. Setting process for open loop start parameter identification (for details, refer to setting process for parameter auto-tuning under vector control 1 in appendix b) select open loop main reference mode...

Page 162

V&t technologies co., ltd. Http://www.Ecodrivecn.Com appendix b control mode setting process 142 open loop setting process (continued) deceleration stop? First dc braking after begin to run from the startup frequency? Begin to run from the startup frequency setting p3.00=0 setting startup frequency ...

Page 163

V&t technologies co., ltd. Http://www.Ecodrivecn.Com appendix b control mode setting process 143 3. Setting process for closed loop start parameter identification (for details, refer to setting process for parameter auto-tuning under vector control 1 in appendix b) select process close loop main ref...

Page 164

V&t technologies co., ltd. Http://www.Ecodrivecn.Com appendix b control mode setting process 144 closed loop setting process (continued) deceleration stop? First dc braking after begin to run from the startup frequency? Begin to run from the startup frequency setting p3.00=0 setting startup frequenc...

Page 165

V&t technologies co., ltd. Http://www.Ecodrivecn.Com appendix b control mode setting process 145 4. Setting process for composite control start parameter identification (for details, refer to setting process for parameter auto-tuning under vector control 1 in appendix b) end vector control 1? Parame...

Page 166

V&t technologies co., ltd. Http://www.Ecodrivecn.Com appendix c faq 146 appendix c faq i. In the case of vector control 2, why did the inverter have abnormal operation? A: (1) check if there exists large difference between the power class of the motor and that of the inverter; a; (2) check if parame...

Page 167

V&t technologies co., ltd. Http://www.Ecodrivecn.Com appendix c faq 147 vii. Why did the inverter report e.Aif analog input abnormal error? A: (1) check if the jumpers of analog input type and control board are properly set. For the analog voltage input, toggle the corresponding channel to the v end...

Page 168

V&t technologies co., ltd. Http://www.Ecodrivecn.Com appendix c faq 148 modification disabled; a: (3) when the modification could not be performed upon running, check if the function code could not modification upon running; a: (4) when display is not available, check if the inverter function code h...